By code you have to derate the ampacity of the wires depending on how many are installed in the conduit not counting the gnd wires just current carrying conductors including the neutral wires.

What size wire for 50 amp welding plug.

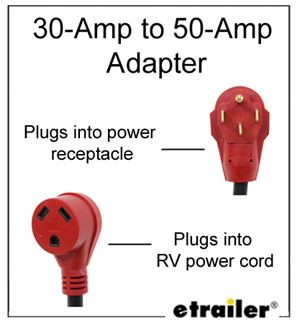

Follow this series of steps one after one to wire the 50a plug in your rv.

Step 1 first and foremost power off the circuit breaker and lock the handle off.

That s beefy wire and it s difficult if not impossible to wrap it around a terminal screw.

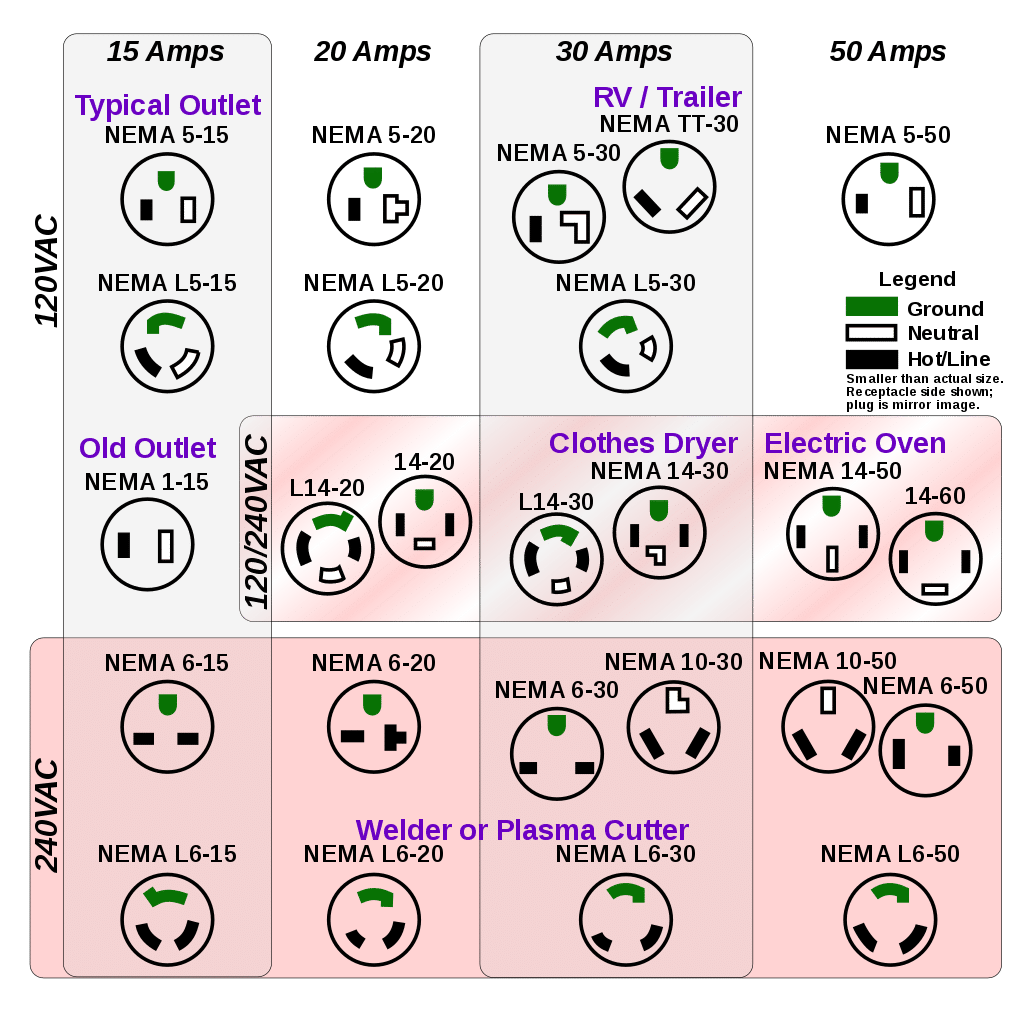

How to wire a 220 outlet for a welder.

A typical 110v mig welder requires 20 amps of input power to generate its 140 amp peak output.

For instance an 8 gauge wire can handle at least 40 amps of current while 50 amps will need a 6 gauge wire.

Buy an 50 amp rv plug from amazon here.

The main circuit breaker should be dead.

A 50 amp service is usual at 120 volts.

Let s find out how to do it the safest way.

Buy ring lugs that you can crimp onto the ends of the wires to make connections inside the plug.

Be sure to purchase a breaker rated at or above the required amperage for your welder the proper gauge wire for that size circuit and the appropriate outlet to match your welder s plug.

You have to derate the wires because of heat they generate.

One of the first things you need to have in a welding shop is a welder properly wired and.

Step 2 once you ve powered off the circuit breaker snap in the 50 amp two pole breaker into the box.

Meanwhile welders operating at 30 40 input amps will need an 8 gauge wire and at least a 40 amp breaker.

Welders operating at 30 to 40 input amps require a 40 amp breaker and 8 gauge wire.

Before that don t go to step 2.

If you re unsure of exactly what to buy ask for help my lincoln electric arc 225 requires a 50 amp 2 pole breaker and a three prong outlet with minimum 6 wire connecting the two.

The major requirement in order to feed the circuit is a 50 amp breaker.

How to wire a 50 amp rv plug.

You need six gauge wires for a 50 amp circuit.

I m getting my work shop ready to do some welding and fabricating.

To wire a 50a plug you will need some tools and follow a systematic procedure.

In order to get this services running you need to have a 4 awg copper wire in order to stay within a serviceable voltage drop which is 3.

Why understanding wire gauge size and amps matters welders must transform low amp input power into the high current output power needed for welding.

Step by step guide.

It s always best to size welder circuits and wiring based on the input current requirements of the welder.

In addition it is always best to size the wiring and welder circuits based on the input current requirements of your welder.